Buckeye bell foundry

The History

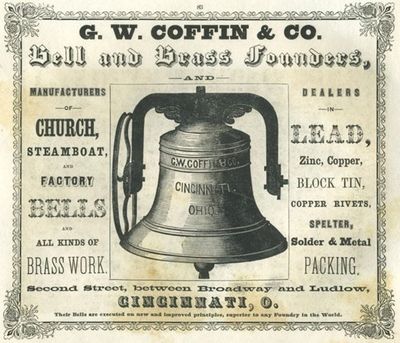

George W. Coffin was born in Brownsville, Pennsylvania on November 17, 1814 to parents from Nantucket. At about 21 years old he followed an older brother to Cincinnati and got a job as a pattern maker in a foundry owned by D. A. Powell. He worked as a pattern maker for about a year and then took another job, becoming a foreman in a small branch foundry of Lyon, Thomas & Company. He only stayed there a short time before leaving and opening his own foundry under his brothers firm T B Coffin & H B Coffin. G W Coffin was the proprietor of the G. W. Coffin Company, a company and foundry he started that was in the business of casting bells and other bronze & brass items. The foundry was located at 102 - 104 East Second Street in Cincinnati between Ludlow and Broadway streets. The Buckeye Bell Foundry, as Coffin named the bell side of the business, cast mostly small to medium sized bells, many of them for riverboats and some churches. He named the foundry after the beautiful Buckeye Trees that used to adorn the banks of the Ohio River in Cincinnati at the time the foundry was established. The foundry cast beautifully decorated bells and very ornate cast iron bell fittings for mounting and ringing the bells.

One of the earliest bells that is known to still exist by this foundry was cast in 1842. G.W. Coffin cast a fire bell that was installed in the newly built St. Mary’s Catholic Church (Now Old St. Mary’s) in Over the Rhine. It was installed in the top of the steeple and rigged up via rope to be rang upon the occasion of a fire in the neighborhood.

By 1843, Coffin’s foundry was doing $31,000.00 in sales. This equated to 40,647 Lbs. of metal including brass, bronze and cast iron melted and poured. At this time he was most casting small single church bells and bells for locomotives and steam ships.

What Buckeye Bells were known for and still remembered for is the intricate relief decorations that the bells carried. Most bells had decorative bands near the shoulder of things like three dimensionally sculpted cherubs playing, beautiful flowers and even dancing ladies sometimes. Some bells had decoration down into the waist as well and some even down around the lip. Coffin must have had a natural artistic mind as his bells were more than something to just make sound. They were truly works of art meant to be seen and heard.

In 1848 George Coffin took on a partnership with G. R. Dudley. Under this new partnership the foundry began casting larger bells and peals of bells, one of the first peals being a large, very beautiful four bell peal that was installed in St. Philomena Catholic Church in downtown Cincinnati. The peal starts with a 3400 Lb. B, then went 1800 Lb. D#, 1200 LB. F# and then the smallest bell was 1000 LB.

In 1849 there is evidence that The Buckeye Bell Foundry cast a chime of bells, possibly the second chime ever to be cast in America. The chime was 8 bells and had a total weight of 9,811 Lbs. This would have been a monumental achievement and the evidence is strong that it happened. Just 3 years later, in 1852 the foundry cast another chime of 20 bells, the largest ever cast in America at the time, that were installed on a river barge named The Floating Palace.

Around 1856, C.A. Coffin, George’s Son became involved in the business and took over operation from his father when he retired. There is not much known about C.A. Coffin except that he focused much more on the steamboat business than his father had. There are no known examples of bells from the foundry with C.A. Coffin’s name on them.

In 1864 or 1865 Ezra W. Vanduzen and Cornelius T. Tift purchased the Buckeye Bell Foundry from G.W. Coffin. E W Vanduzen was born in Cincinnati, Ohio on August 20, 1824. He was the grandson of a German Pastor who had moved his family to Cincinnati in 1816. Vanduzen had gone to work for Coffin in April 1838 at just 14 years of age. His responsibilities included running the engine that supplied power to the machines of the foundry. From there, he learned to make the cores for casting the bells and then started apprenticing under Coffin for casting the bells. In 1856 at just the age of 32 and with 18 years of experience already under his belt, he became a partner to Coffin. At that time C T Tift was already a partner and was taking care of the books.

When Vanduzen & Tift took over operations of the foundry the only thing that changed was the name on the bells. Where before the bells had been embossed The Buckeye Bell Foundry – G.W. Coffin, they now were embossed The Buckeye Bell Foundry – Vanduzen & Tift. The earliest peals documented in the old Coffin bell shape and Vanduzen & Tift name were cast in 1865 for St. Mary’s Catholic Church in Toledo, Ohio. The bells look identical as the Coffin bells with even the same decorations around the shoulder. The 3 peal weighs a total of 6,631 Lbs. The large bell is 58” in diameter, the medium bell 45” in diameter and the small one is 41” in diameter.

It wasn’t long after Vanduzen & Tift took control of the foundry that Vanduzen began experimenting with the shape of the bells. This could have been to try and improve the sound or it could have been that he just wanted to create his own signature profile. It was around 1870 that this new bell shape became the new standard for the foundry. It was a more narrow shaped bell and was not decorative like the Coffin profile bells had been.

In 1870, Vanduzen and Tift purchased The Niles Works Bell Foundry of Cincinnati, a well-established bell foundry that had been started by George Hanks in 1842. George Hanks was one of the most prolific bell founders in the early history of bell founding in America.

1871 would mark a major milestone for Vanduzen. Vanduzen cast a 15 bell chime that weighed 7,290 Lbs. for an exhibition in Cincinnati and then cast another chime of 9 bells that was a little smaller, the following year for another Cincinnati exhibition. There is no information on where these two chimes ended up after the exhibitions. This chime was Vanduzen’s first attempt to get into the musical instrument field with his bells, his continued improvements and new designs. One can’t help but think that the information that was gained from the purchase of the Niles foundry helped Vanduzen realize his ambition to become a bell instrument builder, as this foundry had cast and installed 3 previous instruments, all 3 in Ohio (2 in Cincinnati & 1 in Dayton). Vanduzen cast another chime for the Cincinnati Exhibition the following year as well but didn’t cast another chime of bells until 1893.

Starting in the early 1880’s, the size of the bells as well as the volume of bells that Vanduzen was casting started increasing dramatically. The Second Industrial Revolution was chugging along and probably had a lot to do with this. Documented in the Vanduzen casting books from this time period, you can see where the average size of the bells was increasing as well as the area that they were shipping their bells. By 1886 The Buckeye Bell Foundry cast and shipped more than 13,000 bells which included 130 peals since it was founded, with the largest single bell cast to that time was 7,500 Lbs.

Cornelius Tift died in January of 1890 and was buried in the Spring Grove Cemetery in Cincinnati. For several months Vanduzen operated the foundry alone but the following year C. T. Tift’s wife appointed H.T. Loomis, who was a local business man, music professional and served on the board of directors of Cincinnati Musical Festival Association around the turn of the century, to serve as the administrator of the estate of her husband until she passed away in 1900.

In 1892 E. W. Vanduzen decided that he would build a chime of bells for the Worlds Columbian Exposition that would be in Chicago, IL. Which would be held the following year. The chime was successfully installed in time for the opening of the fair and was played at specific times during the day including 2 regular concerts performed by Professor C. E. Bredberg every day. The chime consisted of 10 bells starting on D1 and included a flat seventh note. The largest bell weighed 3,170 Lbs. and the smallest just 330 Lbs. It was said that the largest bell was arranged on top of the frame in a swinging configuration, as is fairly typical to early American chimes. During the fair, hundreds of thousands of people heard the bells. This brought on many questions about the design and what the cost for such an instrument might be. One of these questions was proposed by a member of the building committee for First Congregational Church in Nashua, NH. who just happen to hear the bells playing while he visited the fair. Later, after the fair had closed, there was discussion between the Church and Frank P. Lotz, now the new general manager of The Buckeye Bell Foundry about the potential purchase of the instrument. During those discussions it was decided that the chime of 10 bells would be expanded to 15 bells. One large bell would be cast bringing the chime to the key of C, adding a 4,500 Lb. bell, and then 4 smaller bells bringing the treble end up to a G2 with a 270 Lb. bell. After the close of the fair, the chime was removed from Machinery Hall and brought back to Cincinnati where it would be expanded. The new bells were cast during the following months and the following spring they were ready to be transported to Nashua. The chime was dedicated at the church in July 1894 and has since rung out into the community for over 125 years.

Over the next the next 13 years the foundry would produce 16 more chimes, the last being in 1906, an 11 bell chime that was installed in First Baptist Church in Scottdale, PA.

What E.W. Vanduzen is probably the most known for is the giant bell he cast in 1895 known as “Big Joe”. This bell is installed in St. Francis de Sales Catholic Church in Cincinnati. The bell weighs approx. 27,000 Lbs. or about 42,000 Lbs. with all of its support and ringing equipment attached.

E.W. Vanduzen went on to run the foundry until his death in 1911. It’s not known for sure how involved with the day to day operations he was but it is assumed that he was around a lot and that his son George was probably performing the duties of General Manager.

After Vanduzen’s death, his son George took over the foundry. He would have been 54 years old at this time and had a good 40 years experience in bell founding. George only ran the foundry for about 5 years and in 1916 left Cincinnati and relocated his family to Sharon Hill, PA. With his relocation/retirement, his sister Martha would take ownership of the foundry and continue operating it as Buckeye Bell Foundry/E.W. Vanduzen Co. Martha appointed Sidney B. Merrill President & Treasurer, his brother Leonard M. Merrill Secretary and her Brother-in-law Dr. Francis Marion Baldwin as Vice President of the foundry to which he served until his death in 1926. It is worth mentioning that at some point after E.W. Vanduzen dies, Martha changed the name to “Van Duzen” (2 words). In an advertisement from The Epworth Herald in 1921, the heading reads “Van Duzen Bells” and then names the company as “The E.W. Van Duzen Co.”

Perhaps one of Merrill’s crowning achievements during his tenure as head of The Buckeye Bell Foundry is in 1923 when the foundry cast and installed a huge peal of 5 bells for Holy Rosary Catholic Church in Indianapolis, IN. The bells, all in swinging configuration are housed in twin towers. The largest of the bells San Salvador, hangs in the West tower by itself and weighs 7,000 Lbs. It is named after the island that Christopher Columbus first landed on in “The New World” when he discovered America in 1492. It is the second largest bell in Indiana, just after the large bell at Notre Dame. The clapper of the bells weighs nearly 300 Lbs. and the yoke and A-stands an additional 3,000 Lbs. The same year, the foundry cast a large four bell swinging peal for St. John’s Catholic Church in Covington, KY. which had just been built. The combined weight of the four bells is just over 8,000 Lbs. The thing that makes the peal unique are the notes, which are C, D, E & F. The large bell carries an inscription “TO THE MOST SACRED HEART OF JESUS”. The D bell has ”TO THE IMMACULATE VIRGIN MOTHER OF GOD” inscribed on it. Bells three and four say “TO ST. JOSEPH” & “TO ST. JOHN THE APOSTILE”. The bells were blessed by Bishop Francis W. Howard on Sunday August 3, 1924.

In 1937 the massive flood that struck the Ohio and Mississippi Rivers destroyed a lot of the foundry and the records. This was the first of several major events that started the spiral downhill for the foundry and would eventually lead to its closing less than 13 years later. A few years after the flood, World War ll started and like all the other bell foundries, the raw material for making bells became impossible to purchase because it was all going to the war effort.

On April 5, 1949 the 71 year old Sidney Merrill and his brother 62 year old Leonard signed a promissory note to borrow $14,000.00 payable two years after date with a 6% interest, payable semi-annually, the sum of $17,500.00 with interest from June 5, 1953. The promissory note was to a Joseph H. Homan a local businessmen and metals dealer. As collateral for this loan, the business as well as the property were put up. It was only a few months later on July 27, 1949, Martha Vanduzen died at the age of 88 in Blanchester, Ohio. She was laid to rest in the Vanduzen family plot in Spring Grove Cemetery in Cincinnati.

Ultimately the Merrill brothers were not able to pay the note to Holman so he took over the foundry operation in 1953. The foundry remained casting bells for the next 4 years but in 1957 they were forced to close and the contents of the foundry were auctioned off.

The Buckeye Bell Foundry holds a very special place in the history of bell founding in America. They cast the largest bell ever to be made in the US, they cast the second chime of bells in America and they likely cast the very first traveling chime of bells that were installed on the Floating Palace.

ceCopyright © 2025 T Verdin Legacy Bellworks - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.